Refurbishment, overhaul and rebuild

If a product works well, you repair it and don’t necessarily replace it.

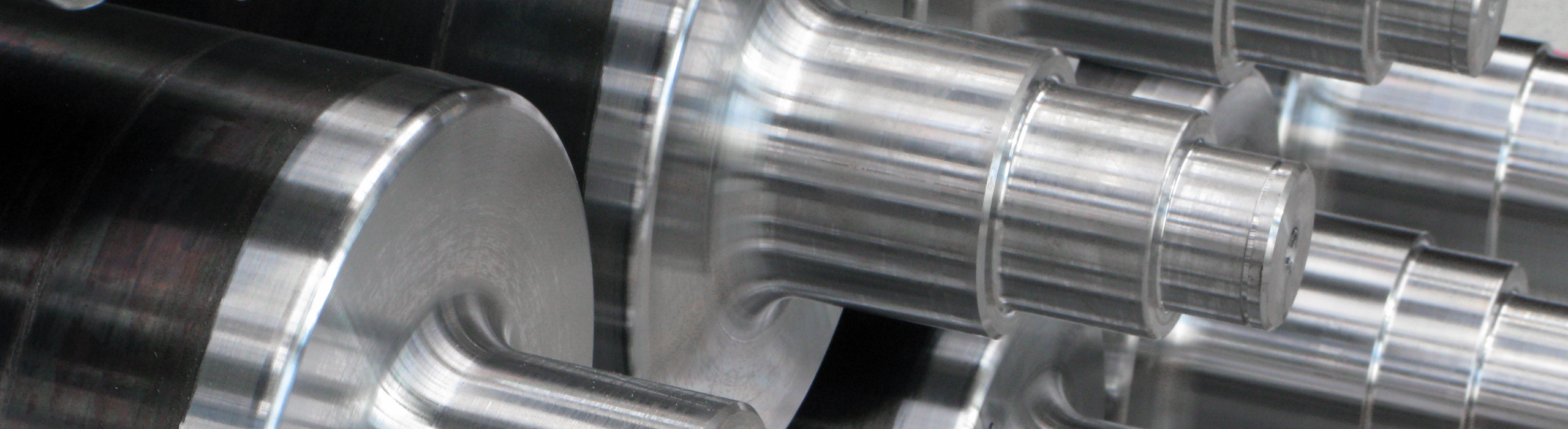

When the need arises, we do refurbishments of our machine on site, replacing from wear parts, to screw shafts, screen and filter segments up to more complex parts like drive replacements or structural improvement. Our technical teams can work around in shifts to meet the shutdown time specified by the customer. After the optimization of the machine has been completed, the full performance of the machines is restored with the restart.

If refurbishment has been delayed for a long time, we can still help. In complex cases, we dismantle the machines and refurbish them in our specifically equipped workshops. In this way, we can extend the service life of the machines and even optimize them with additional functions required for constantly evolving technology.

Advantages:

- Modern equipment installed

- Latest technological development

- Bellmer rental units during rebuilds

- Looks like a new machine

- Complete overhauls by Bellmer

We have dedicated internal teams, who after site visits and discussions can offer various upgrades to the machines, by adding the latest technologies and in-house developed parts that optimize performance beyond that of the original machine. Here, parts such as new drive solutions to save on energy costs or wear protection to save on spare parts can be discussed and implemented into the machines.

During the “machine downtime” we offer rental units to bridge the gap until your machines are online again.

You can be absolutely sure: Bellmer offers you the best option for refurbishments, machine upgrades and optimizations.

Get more information

Our specialists are looking forward to take on your new overhaul and rebuild project. Contact us for further information and learn more about our overhauls and rebuilds process: upgrade@bellmer.com