Screw Press – AKUPRESS AP/AS/AX

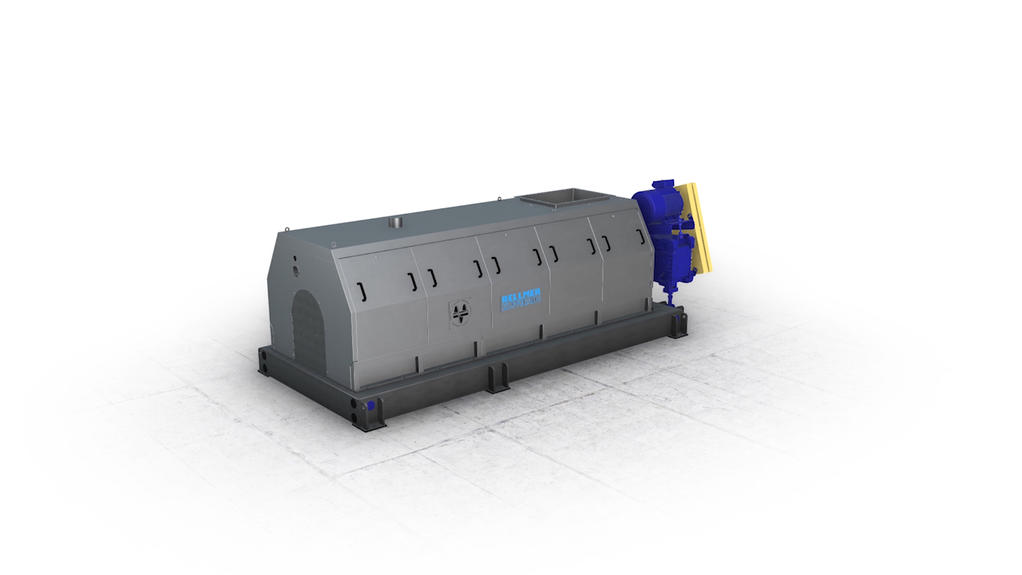

In the field of reject handling, we offer two different screw press lines: AKUPRESS AP/AS for high dry content and AKUPRESS AX for the maximum dry content in the market. Here we build on the experiences gained from more than 700 AKUPRESS screw presses sold and delivered. All our screw presses have easy and user-friendly handling. During the production process, our customers rely on the closed, compact and robust AKUPRESS.

Learn more details about our two different screw press lines.

Advantages:

- Maximal dry contents

- Patented torque control by movable screen basket (AKUPRESS AX)

- Flanged screw shaft

- Interchangeable screen basket system

- Closed hood construction

AKUPRESS AP/AS

The AKUPRESS AP is available in three sizes between 500 and 800 mm screw diameter that handle 70 to 200 dry tons of pulper reject per day. Here, the discharge opening allows that large particles directly exit the press zone. The high one-thread spiral enables the transportation of large particles without any blockings. The bearings on both sides support the entire high-pressure range, stabilize the screw shaft and thus ensure high availability. The interchangeable screen basket system makes maintenance easy. The user controls the process easily by adjusting the pneumatic pressure of the cone that exhibit the counterpressure at screw press outlet.

The AKUPRESS AS line shares the process control and robust design with the AKUPRESS AP, but it has a completely closed cover system and different screw geometries, thus providing best conditions for fine reject and pulp mill reject. For the latter suction openings are available for odour and vapour control. The AKUPRESS AS is available in five sizes from 250 to 800 mm screw diameter.

AKUPRESS AX

The AKUPRESS AX works with much higher torque than the AKUPRESS AP/AS and thus provides the maximum mechanically possible dewatering performance. The high torque is controlled by an axial adjustment of the screen basket to the screw shaft and by continuous adaption of the press zone length to the respective substance characteristics. The AKUPRESS AX is available in seven sizes from 250 to 1000 mm screw diameter, thus is able to handle up to 250 tons per day of waste paper reject.

Get more information

Our screw press specialists are looking forward to taking care of your next reject project in the paper industry. Learn more about our various screw press applications in the paper industry.

Just contact us: screwpress@bellmer.com