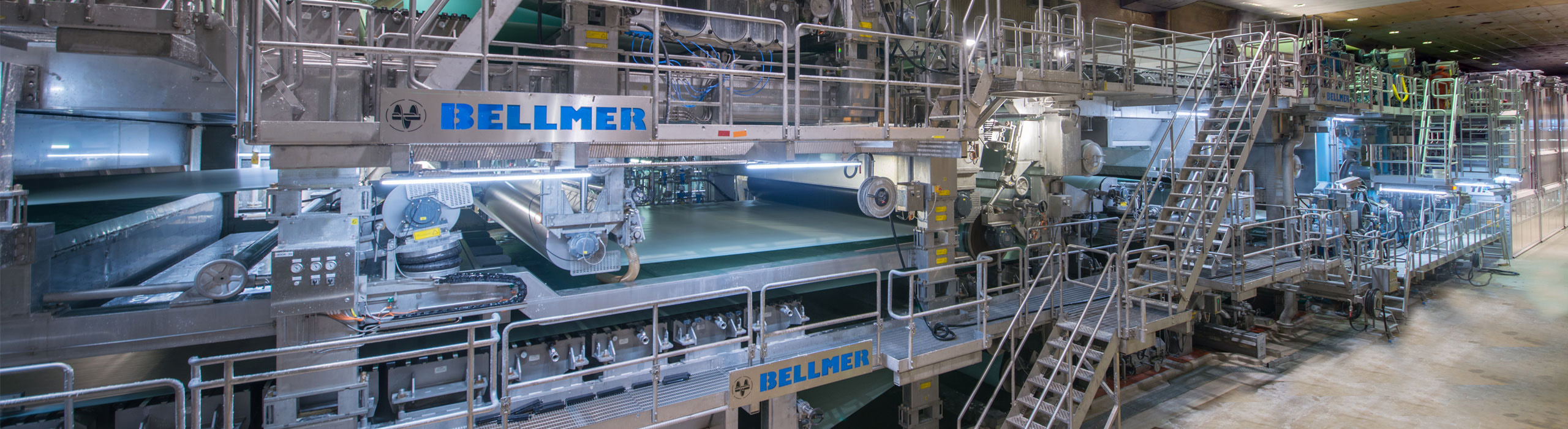

Turbo Wet End Solutions

No matter what kind of fiber web you aim to produce, what speed you choose to run, and whether you use primary or recycled fiber – the wet end holds the key to any best sheet. Our TurboSeries from Germany and Finland provides individually designed products for the wet end area starting from the headbox via the wire section to the press section. Our technical design service incorporates stock characteristics, space-technical considerations as well as specific automation solutions.

Treat your wet end to the attention it deserves by working with Bellmer. You will find us highly focused on your results, and flexible in our approach. Decades of satisfied customers are the result.

Get more information

Our specialists are looking forward to taking on your new project.

Just contact us: wet-end@bellmer.com

Or just read more about our latest Wet End projects and news:

- Improvement of paper qualityThe TurboShaker enables the sheet formation and other paper properties to be influenced permanently and [...]Read more

- TurboPress for Aryan Paper Mills PVT LTD.To make the paper production process even more effective and flexible, Aryan opted for a TurboPress with [...]Read more

- Ahlstrom launches new glass fiber tissue lineAhlstrom proudly launched the new glass fiber tissue line in Madisonville and Bellmer is one of the main [...]Read more