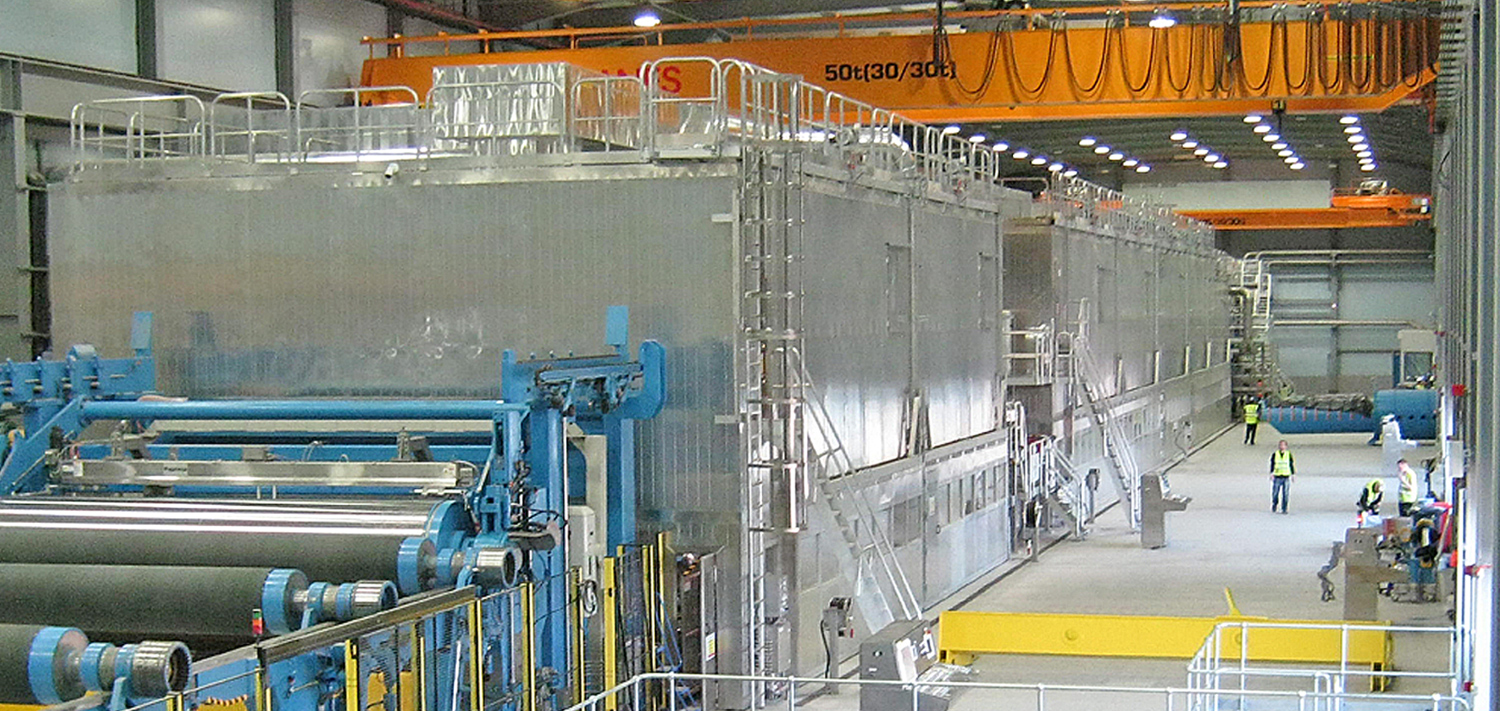

New Hood Installation in Drying Section

The installation of a new hood and the rebuild of the dryer section have reduced steam and electricity consumption of PM 1 at PAPETERIES DU RHIN (Illzach – France). The efficiency of the heat recovery system has also been increased.

The renewal of the existing hood has facilitated working with high dew points and the achievement of optimum energy consumption. Hot and humid air leaks inside the hall can be avoided, too.

The following equipment has been supplied:

- Replacement of the existing panels with new ones, manufactured with Thermal Bridge Break and Best Insulation Capacity

- Improvement of Hood Closures, improving the Air Tightness

- Pocket Ventilation Boxes in areas with higher humidity

- Aerothermic Installation Control System – Zero Level Automatic Control; Allowing minimization of required Air Blowing Flow, it allows energy saving in terms of the electrical and steam consumption required for blowing air heating

- erothermic Installation Control System – Dew Point Automatic Regulation System; Allows minimization of the Fumes Exhaust Flow, by means of Water Content Automatic Control of Exhaust Fumes

Get more information

You can get further information about the Bellmer Hood and Ventilation Systems here.

Or just contact us: air@bellmer.com